BLOG

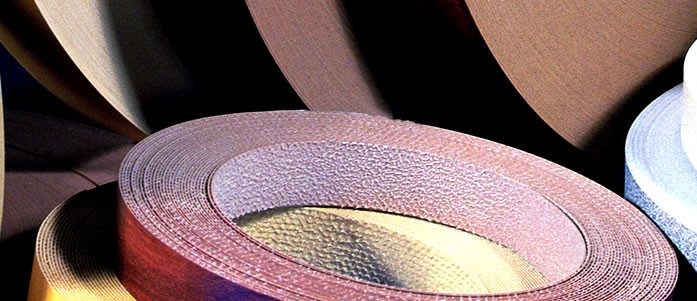

Edgebandings in Pre-glued Rolls

When we develop our portfolio of products, we don't only consider the big producer of furniture. But we think of those who can cover the edges without having to invest big amount of money to the machinery.

Keeping this in mind, we offer pre-glued edgebandings in PVC, melamine and veneer. This way, we serve our smaller customers and help our intermediary distributors to supply edgebandings to anyone from big to small producers.

Pre-glued edgebanding is the edgebanding that is coated with hot melt in the back side. And hot melt adhesive is activated by heat of minimum of 130 º C - 170 º C. It can be activated with standard iron or hot air blower.

The good application of pre-glued edgebanding can produce an excellent adhesive as if it is done with machinery.

Why would we prefer to offer hot melt adhesive products rather than self adhesive?

No matter which self adhesive tape is used on the back of the edgebanding, there is still possibility of having the edgebanding peel of from the panel's edge. Yet with hot melt backed edgebanding, we decrease this risk to a minimum level.

At TECE, we can supply our complete range with hot melt pre-coating.

Thus, we offer the following products:

Pre-glued PVC edgebanding: Any thickness between 0.4mm and 0.8mm is possible to have the hot melt pre-coating.

Pre-glued Melamine edgebanding: This is the most common and least expensive hot melt pre-coated edgebanding.

Pre-glued Veneer edgebanding: The natural veneer edgebanding can easily be applied with iron or hot air blower.

The width of pre-glued edgebanding can change between 16mm and 120mm depending on the demand.

For more information, please get in touch with us. Someone from our company will get back to you within 24 hours.