ABS EDGEBANDING

ABS Edgebanding: The Ecological Solution for Edging Needs

As the global population grows and consumption increases, the ecological balance of our planet is at risk. In the world of polymers, one of the most environmentally friendly options is ABS (Acrylonitrile Butadiene Styrene).

At Tece, we are committed to serving our customers who want to be more eco-friendly by producing ABS edgebanding in addition to our full range of products.

ABS is a chlorine-free polymer that has similar properties to PVC, but it can be burned with general waste without releasing harmful pollutants.

Our vision at Tece is to provide a complete range of edgebandings, and by offering ABS edgebanding, we and our partners are better able to serve our customers.

ABS has been the choice of many furniture manufacturers worldwide, particularly in Europe, in recent years.

We will match your color...

At Tece, like our other products, we must produce colors based on the needs of our customers. For this reason, we can match and produce any color based on the samples of our customer. Please send us a sample so that we can send you a matching sample for consideration. For further discussion, please get in touch with us.

A Better World for Future

Whatever we do, we value human life; we value the world. We have only one world; and we have to take care it to the best of our ability. To this end, at TECE, no matter what we produce, we make sure that we work in proper way, respecting the nature and the environment. ABS edgebanding is a good solution for a better world. Because the waste of ABS can be burned; it produces no hazardous emission for the air.

At Tece, we are committed to serving our customers who want to be more eco-friendly by producing ABS edgebanding in addition to our full range of products.

ABS is a chlorine-free polymer that has similar properties to PVC, but it can be burned with general waste without releasing harmful pollutants.

Our vision at Tece is to provide a complete range of edgebandings, and by offering ABS edgebanding, we and our partners are better able to serve our customers.

ABS has been the choice of many furniture manufacturers worldwide, particularly in Europe, in recent years.

We will match your color...

At Tece, like our other products, we must produce colors based on the needs of our customers. For this reason, we can match and produce any color based on the samples of our customer. Please send us a sample so that we can send you a matching sample for consideration. For further discussion, please get in touch with us.

A Better World for Future

Whatever we do, we value human life; we value the world. We have only one world; and we have to take care it to the best of our ability. To this end, at TECE, no matter what we produce, we make sure that we work in proper way, respecting the nature and the environment. ABS edgebanding is a good solution for a better world. Because the waste of ABS can be burned; it produces no hazardous emission for the air.

-

Thickness from 0.3 to 3.0mm

Thickness from 0.3 to 3.0mm

-

Width from 9mm to 410mm

Width from 9mm to 410mm

-

Minimum tolerance on color

Minimum tolerance on color

-

Eco-friendly recyclable

Eco-friendly recyclable

-

Perfect matching

Perfect matching

-

High durability

High durability

-

Healthy

Healthy

-

Customizable

Customizable

Tece ABS edgebanding is produced using calendar technology, which allows for better calibration and consistency in production. Additionally, this method makes our company more flexible, as we keep all stock in master rolls of 410mm wide. Once an order is received from customers, these master rolls are slit to size or, alternatively, the material can be shipped as a jumbo roll and then slit by the customer to the desired size.

The ABS edgebanding is treated with a special primer after extrusion, which enables it to adhere to the edges of the board with hot melt adhesive. The quality of the primer is of the utmost importance and at Tece, we only source primer from reliable and reputable suppliers such as Jowat.

After the jumbo rolls are ready, they move on to the next phase: UV PRINTING. Similar to our other products, we use UV printing technology which allows for top-quality printing with sharp and perfect details. We can match any color or design from any board producer.

Our UV printing system makes the product much more resistant to solvents, scratches, and UV light. It's worth noting that all edgebanding have UV top coat, but only a few use UV printing as it is more expensive than other printing techniques.

Once this phase is complete, the master rolls are ready to be slit to size or dispatched as a master roll. The thickness options range from 0.3mm to 3.00mm, width options range from 9mm to 410mm, and roll length can be any length based on customer demand and thickness.

After this phase, the master rolls are ready to be slit to the size (or alternatively, they can be dispatched as master roll).

The ABS edgebanding is treated with a special primer after extrusion, which enables it to adhere to the edges of the board with hot melt adhesive. The quality of the primer is of the utmost importance and at Tece, we only source primer from reliable and reputable suppliers such as Jowat.

After the jumbo rolls are ready, they move on to the next phase: UV PRINTING. Similar to our other products, we use UV printing technology which allows for top-quality printing with sharp and perfect details. We can match any color or design from any board producer.

Our UV printing system makes the product much more resistant to solvents, scratches, and UV light. It's worth noting that all edgebanding have UV top coat, but only a few use UV printing as it is more expensive than other printing techniques.

Once this phase is complete, the master rolls are ready to be slit to size or dispatched as a master roll. The thickness options range from 0.3mm to 3.00mm, width options range from 9mm to 410mm, and roll length can be any length based on customer demand and thickness.

After this phase, the master rolls are ready to be slit to the size (or alternatively, they can be dispatched as master roll).

- Thicknesses: between 0.3 and 3.00 mm.

- Width: between 9mm - 410mm

- Roll length: any length based on the demand and thickness

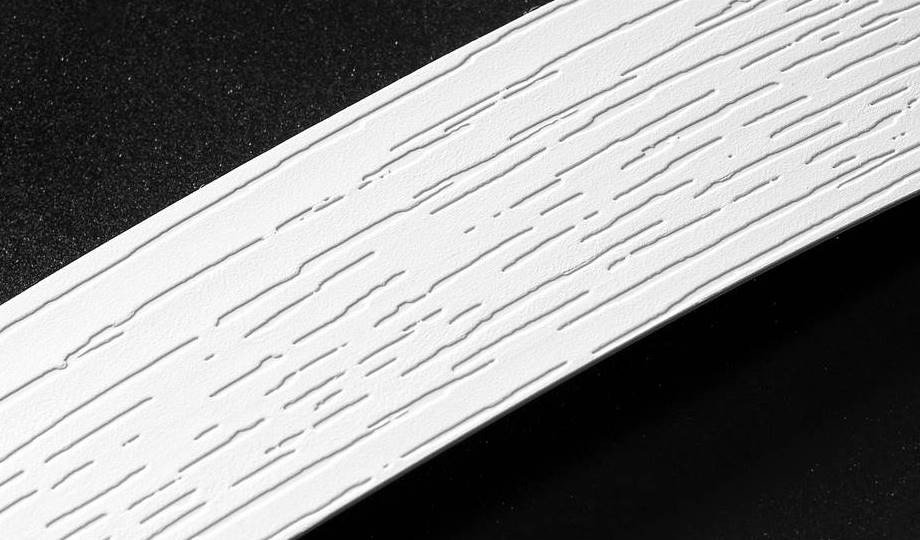

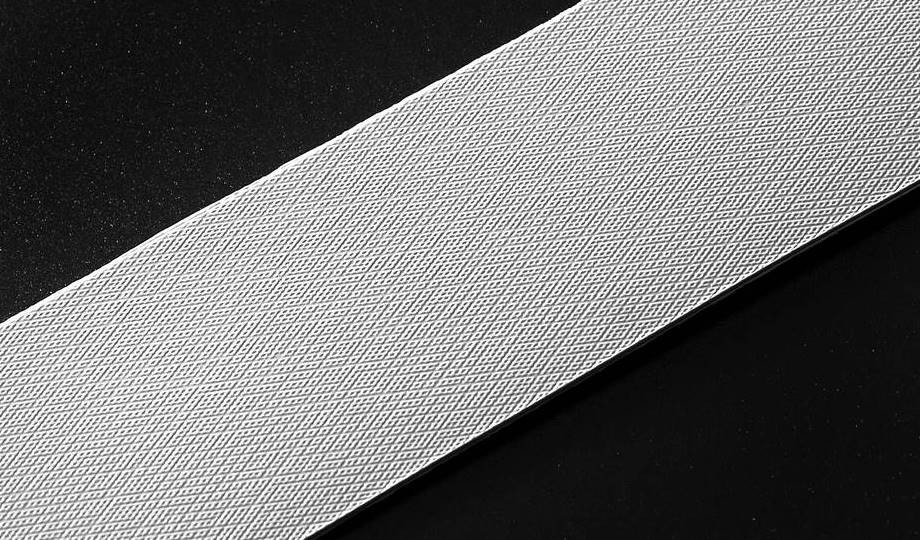

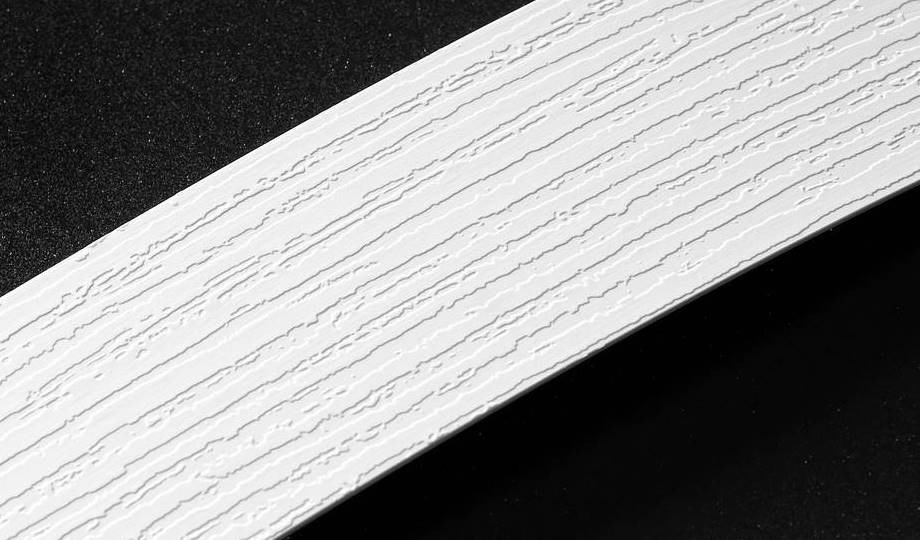

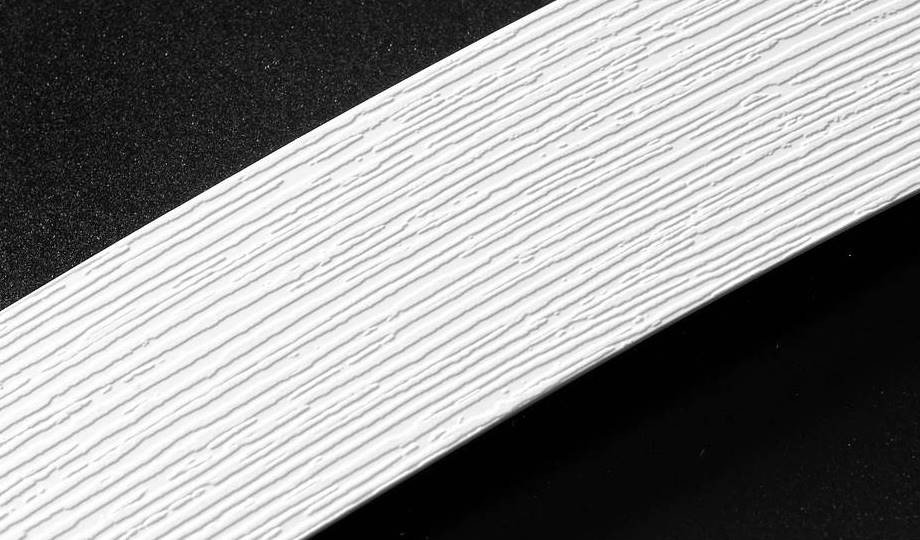

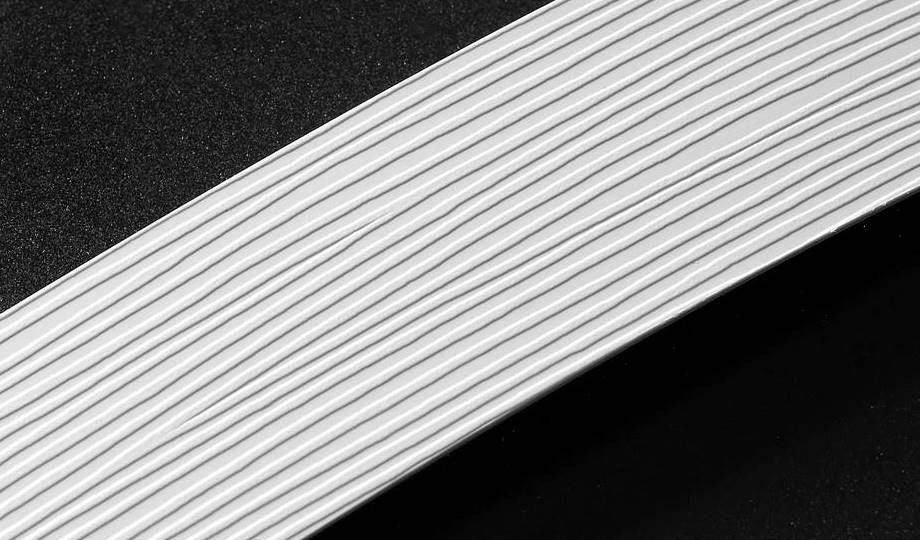

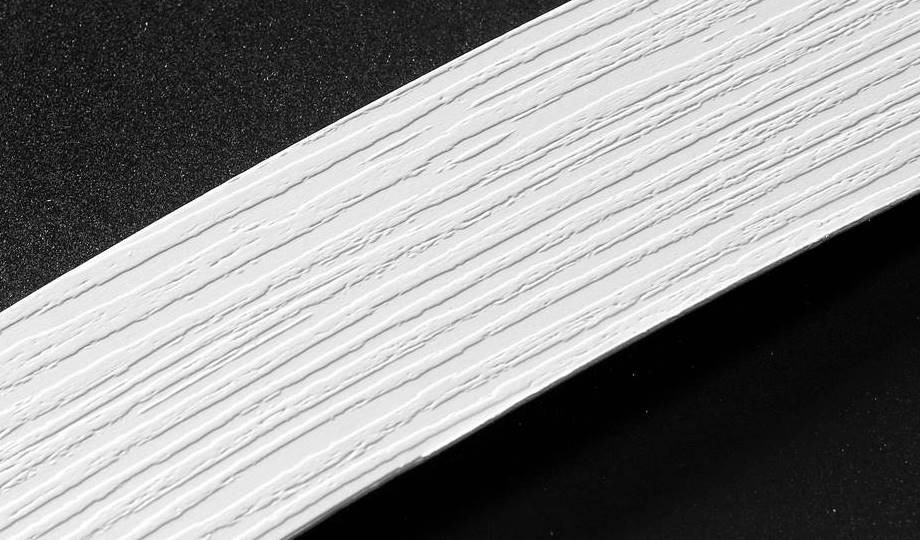

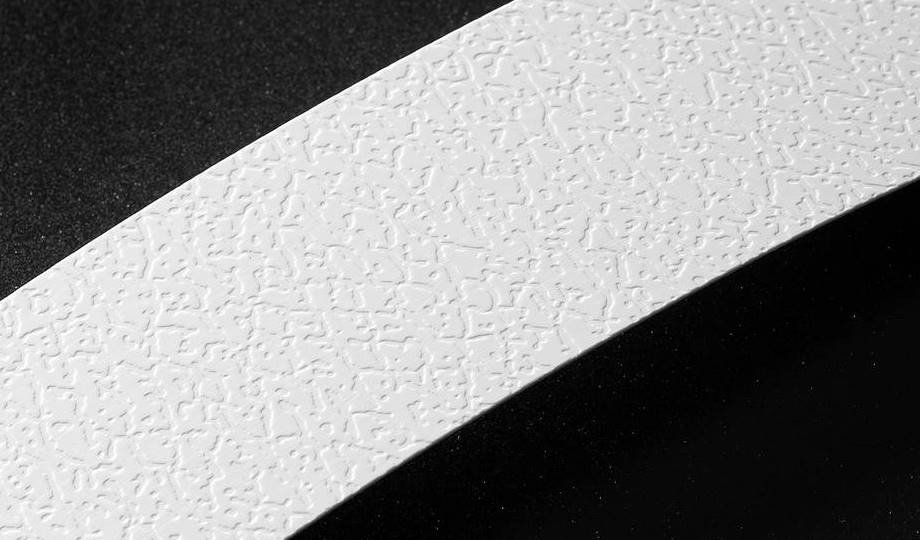

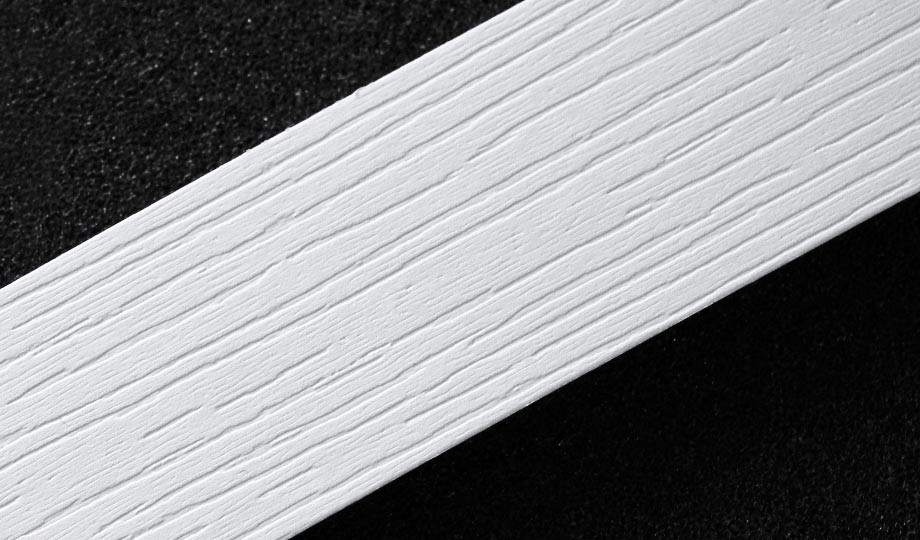

Just as important as the patterns is the tactile feel and surface type on the product. Thanks to the harmony of the tiny protrusions on the surface with the pattern, a much more realistic image is obtained.

Check the surface types below.

Check the surface types below.

Surface Types

PDF FILES :

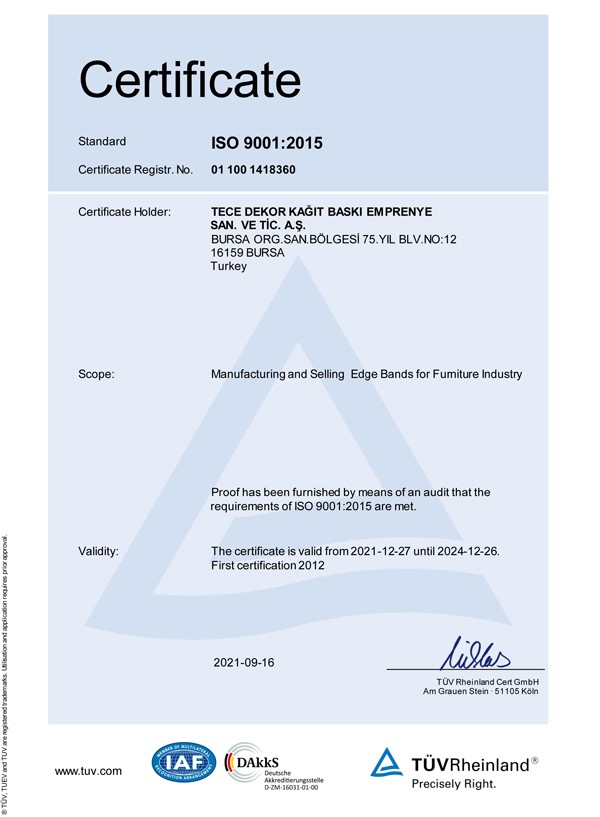

CERTIFICATES GALLERY :

TECE is ready to listen to your comments and suggestions. Just fill out the form completely so we can get back to you asap...