PVC EDGEBANDING

PVC itself is a very strange material that stands the risk of reacting over time. If not well-examined or made with proper ingredients, it can shrink or expand. This is a risk that our customers don’t need to think about when using our products.(Why would they expect?)

UV Printing is The Best/ UV Printing at its Best

We use UV printing and UV lacquering system and thus the finished product contains no solvent. Furthermore, our product contains no lead!Our PVC edgebandings are accurately matched with the panel surfaces which are crucial features in the furniture-making industry today. Further to that, they are consistent in thickness and color.

What to expect from Tece Edgebanding

Whenever you purchase any of TECE’s edgebandings, expect nothing less than the following qualities;- Durable against all external damages and hits.

- Aesthetically appealing with its perfect designs and impressive look.

- Diversified with plenty of colors that perfectly match the chipboards.

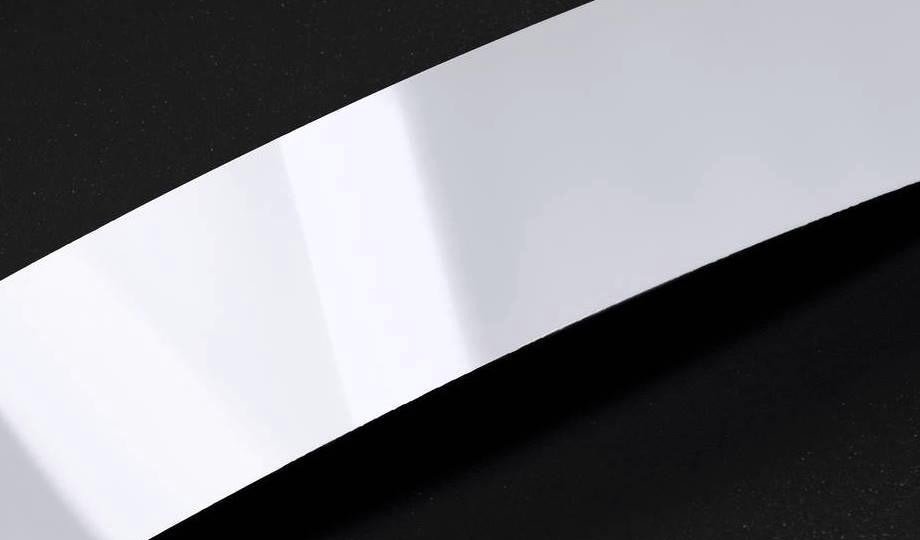

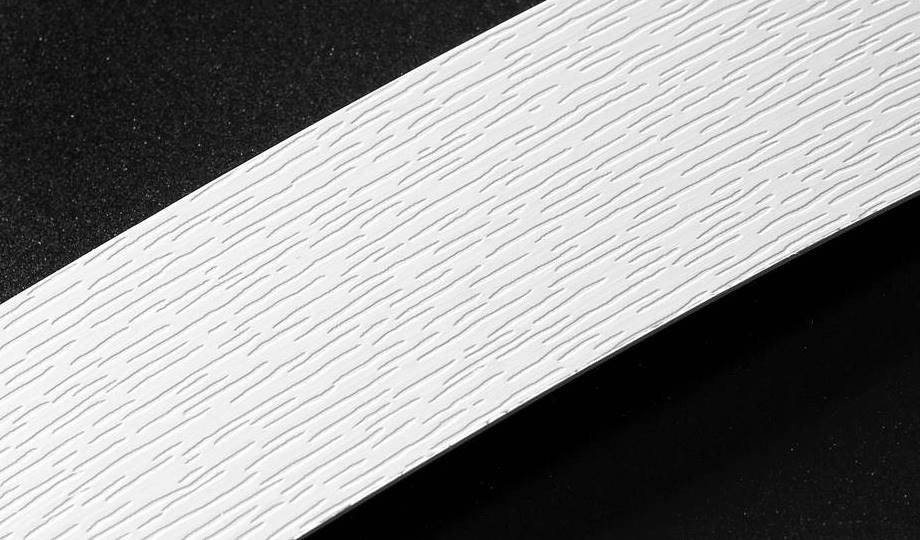

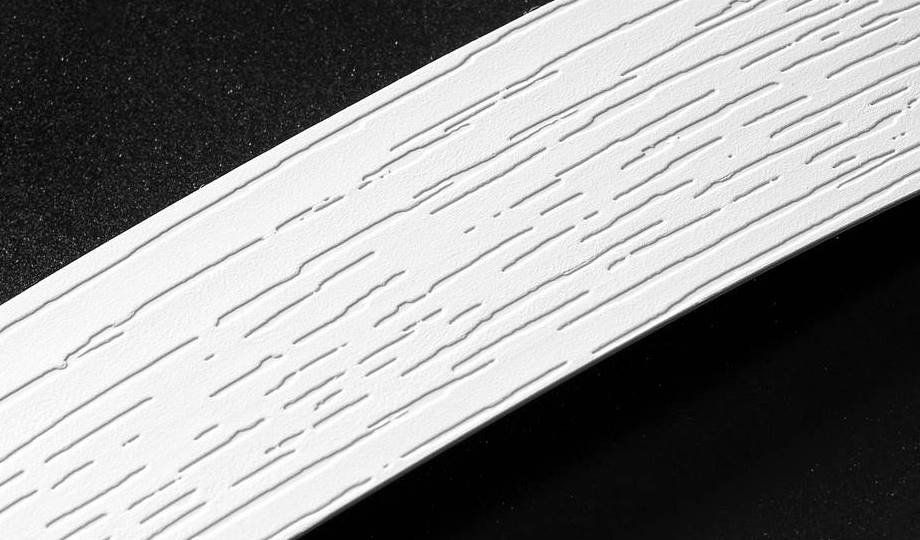

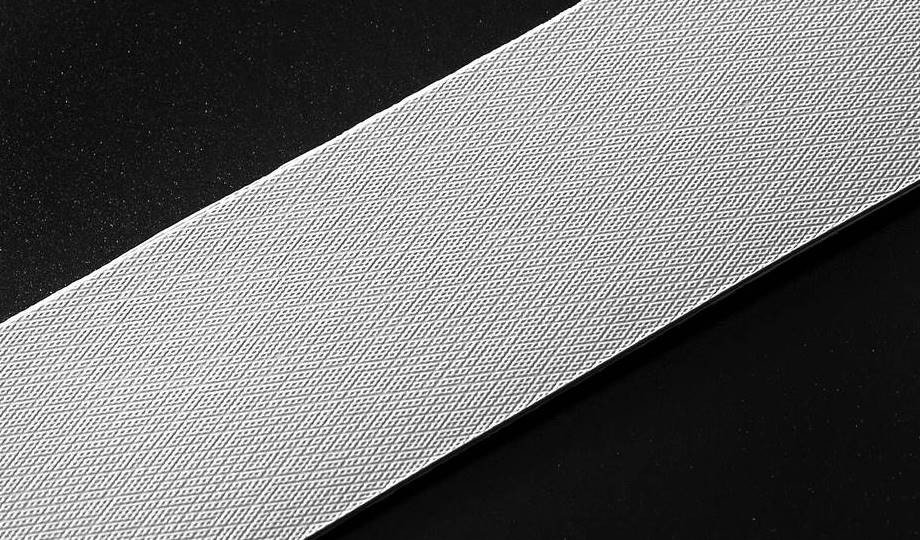

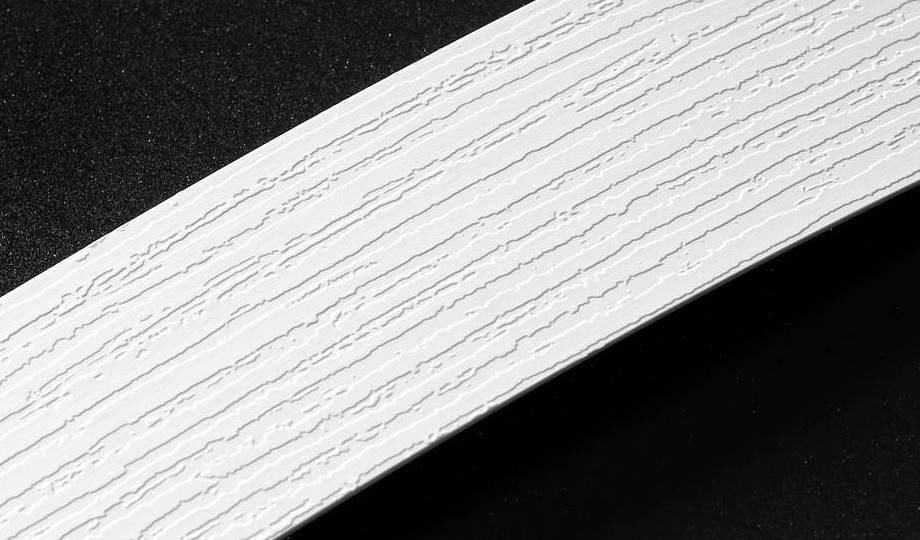

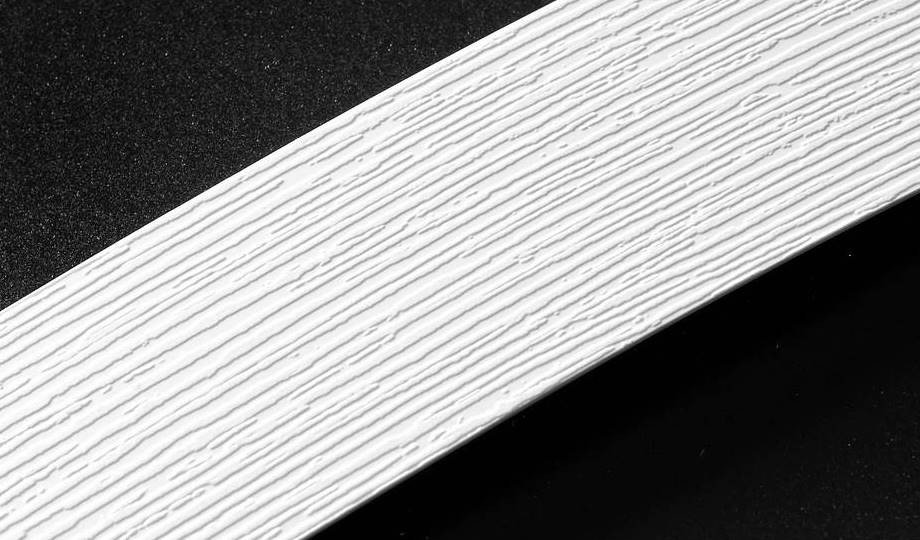

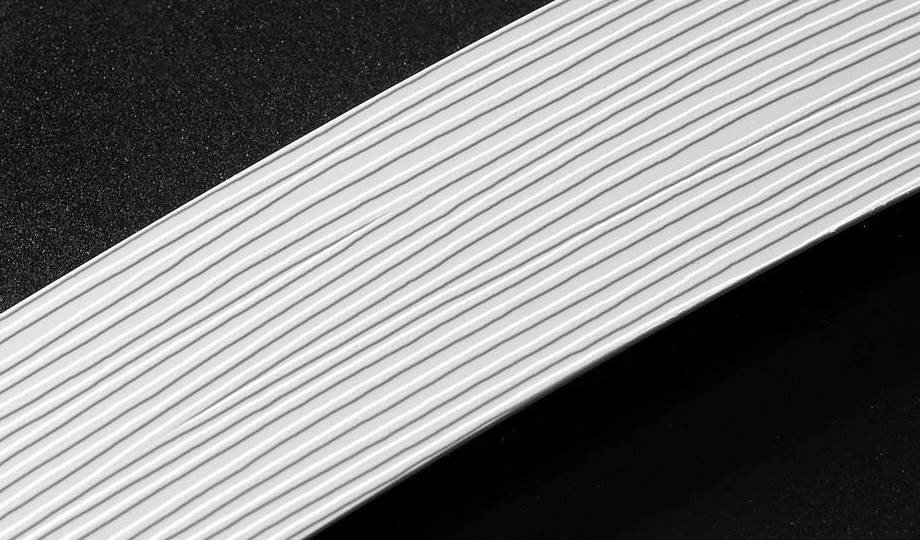

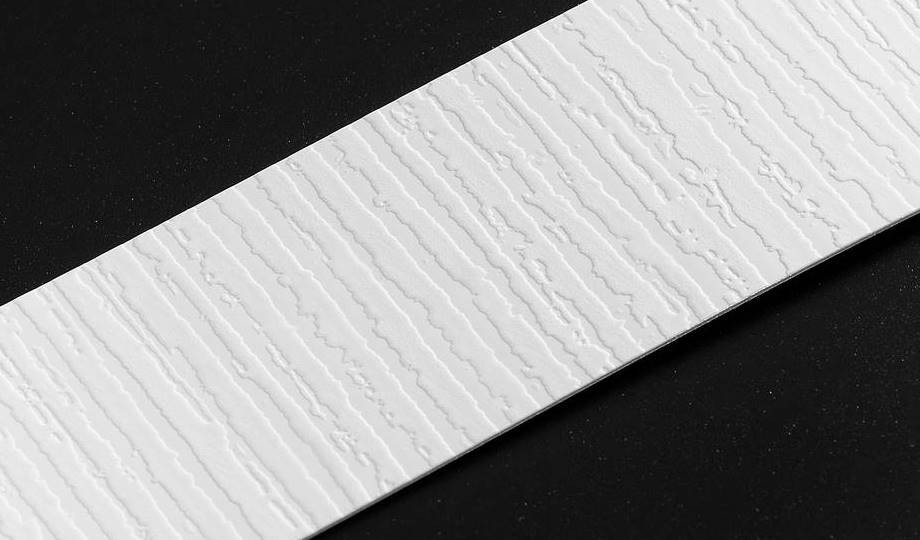

- Customized; It is possible to choose from smooth, textured, high gloss and wood grain colors.

The standard thicknesses of PVC are 0.4mm, 0.8mm and 2mm. It is, however possible to produce any thickness from 0.3mm to 2mm if demanded.

In our productions, we make jumbo rolls in widths of 610mm. We can slit them to any width that you would prefer. It is up to your preference, contact us and we will strive to have it for you.

-

Thickness from 0.3mm to 2mm

Thickness from 0.3mm to 2mm

-

Width from 9mm to 610mm

Width from 9mm to 610mm

-

Minimum tolerance on color

Minimum tolerance on color

-

Eco-friendly recyclable

Eco-friendly recyclable

-

Perfect matching

Perfect matching

-

High durability

High durability

-

Customizable

Customizable

In the modern world, companies must find ways to reduce the cost of production and make their products affordable.

For this reason, Nowadays furniture producers use boards with the best possible surface finish or even with pre-finished surfaces. In this way, they can apply as little paint as possible to achieve the desired color.

How about the edge?

The surface of the board can be very smooth but the edge is always rough after cutting the panel. For this purpose, we are producing a special product called 'Paintable PVC edgebanding'. The polyurethane or UV-based paint will adhere to this specially produced PVC edgebanding. In this way, the furniture producers do not have to apply as much paint or do not have to sand the edge of the panel as much.

The standard thicknesses of PVC are 0.4mm, 1mm and 2mm. It is, however possible to produce any thickness from 0.4mm to 2mm if requested. In our productions, we make jumbo rolls in widths of 610mm. We can slit them to any width that you would prefer. The preferred thickness in high gloss finish is between 0,8mm and 1mm

Following trends of furniture is the pillar of our R&D department. If we do not keep up with the new developments, we cannot fulfill the demands of our customers and the market.

Since 2020, matt surfaces are becoming popular in kitchen, living areas and more.

With our special matt coating, we can imitate the exact finish of matt surfaces. The gloss level can go as low as 3 at 60 degree angle.

Offering a full range of edgebanding (whether it be melamine, PVC, pre-glued or other) has always been our core business mission. Keeping this in mind, we have accomplished producing PVC with hot melt glue backing.

Now, carpenters do not need a machine to apply the PVC edgebanding to the panel. They can apply the edgebanding with a standard iron. Yet, they can only do it through using this specially produced PVC edgebanding.The hot melt is specially designed and produced for this purpose. Its melting point is lower than standard glue.

When applying, carpenters must use an iron cover or some sort of paper between the iron and PVC to protect the surface from heat-related damages.

You can watch the video below as to how to use pre-glued PVC edgebanding:

The pre-glued PVC edge is available in thickness of 0.4mm for iron application. The thickness can go up as high as 0.8mm. Above 0.4mm, a hot air blower must be used. Otherwise, ironing will not melt the glue due to the thickness of the product.

Tece plastic wrapping foils are 100% match to the edgebanding; therefore, it will be matching to the board or any other design or color requested. Foils are produced in jumbo roll with the width of 610mm. So, it can be slit to any size. Thickness is ~0.3mm. It is possible to use EVA hotmelt or PUR glue in the wrapping machine.

It is all about trends

Like all other commodity products, trends also rotate in furniture industry. Sometimes, furniture with straight lines is the trend; sometimes, furniture with radius corners is the trend. To furniture makers who produce designs with radius corners, we offer PVC / ABS foils in special thickness and flexibility to their products. This product can be used for wrapping profiles, frames, table legs, cabinet doors and more.

Available PVC / ABS

In the below, you can see a small sample of special plastic foil. Please touch and feel the flexibility of the products. This product is available in both PVC and ABS. It is also possible to get softforming melamine foil. Yet, plastic foils are much stronger.

Available in any width

From 14mm to 610mm, the customer can get in any width that they need. We will match the color to the panel or any other product desired by the customer.

Check the surface types below.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

PDF FILES :

- Material Safety Data Sheet

- PVC Confirmity

- Technical Specifications PVC

- Technical Specifications Pre-Glued PVC

- TUV Test Certificate PVC