BLOG

Archieve

BLOG

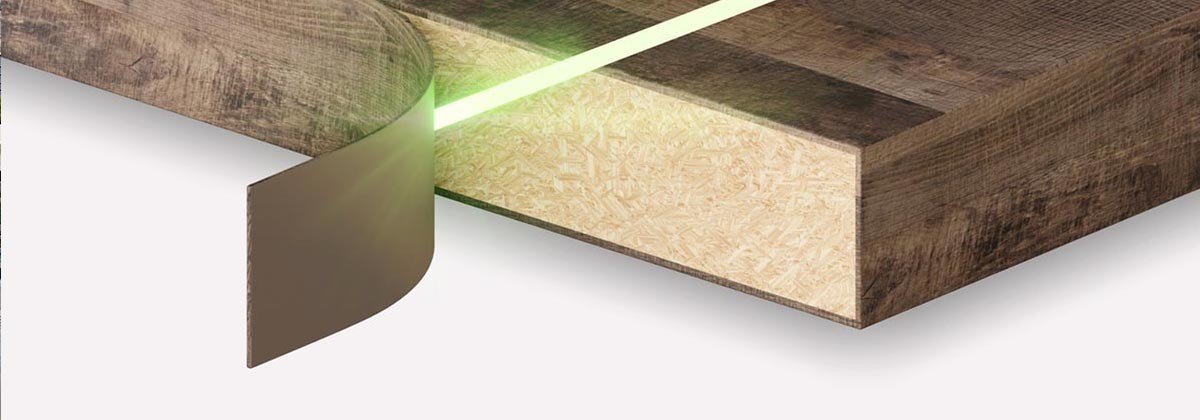

Why the World not Ready for Laser or other Zero-Glue technologies?

It has been more than 10 years that zero glue line technology has been introduced to the furniture industry. Leading edgebander producers such as Homag, Biesse, SCM, and many others have promoted it in many exhibitions around the world. Each company gives a different name to it: Laser, Airtec, Airtronic. Yet, somehow, the technology never had a kick-start. It looks like something is wrong with the strategy.

On this opinion page, we will share our technicians' opinions on this matter.

In many exhibitions around the world, we have been meeting with customers that are asking how to get edgebanding for their zero glue technologies; some of them already have the machine installed, some are considering making the investment; and common point among those visitors is the concern of getting the correct edgebanding. As a matter of fact, those who already invested in the technology told us that they are mostly using conventional EVA glue option on their line. That is because they can’t get enough colors or products.

From our opinion, there are few things that have to change in order for this product to be successful.

What is the future of Zero-glue line technology?

From our opinion, this technology is so great; yet, the unavailability of edgebanding and the cost of it, it is not feasible for the customers to accept it. Of course, there are some who use it but it is not at their full capacity. At TECE, we developed our own technology and applied for our patent for the functional layer.

We are working on a strategy to lower the costing of edgebanding to the minimum level to see if we can see a positive reaction from the market. You can get in touch with us to see what we can do together.

Below, you can see our articles and products on this range.

On this opinion page, we will share our technicians' opinions on this matter.

In many exhibitions around the world, we have been meeting with customers that are asking how to get edgebanding for their zero glue technologies; some of them already have the machine installed, some are considering making the investment; and common point among those visitors is the concern of getting the correct edgebanding. As a matter of fact, those who already invested in the technology told us that they are mostly using conventional EVA glue option on their line. That is because they can’t get enough colors or products.

Why Zero-Glue line is perfect?

Because it produces a seamless joint between edgebanding and the board; this results into below advantages:- Finishing quality: The zero line technology produces the best and most invisible glue line possible. Even polyurethane glue cannot come close to its ultimate quality.

- Glue: the edgebanding supplier takes care of the functional layer, in other words, the glue. This enables to have best possible adhesion.

- Machining: Since there is no glue pot, there needs to be no cleaning of it. Also, you can start and stop without worrying about glue change or damaging the glue due to inactivity.

From our opinion, there are few things that have to change in order for this product to be successful.

- Equipments: It is still a high investment on the tool to get this feature on edgebanding machines. If anybody can come up with a simpler solution that does not require as much technology, energy and also patent, this can be affordable for many. In other words, the entry barrier needs to be lowered to be affordable for most of the industry.

- Availability of edgebanding: this is the most important issue on this technology. Due to lesser demands, most edgebanding producers do not even carry this range in their collection. Secondly, there is the patent issue from other producers who got a patent for a mixture polymer. This also results into higher costing for the product for the furniture producer. Again, if a product can be successful, it has to be affordable. If it is not affordable, the market is limited and most of the public cannot reap the benefit of such good technology.

What is the future of Zero-glue line technology?

From our opinion, this technology is so great; yet, the unavailability of edgebanding and the cost of it, it is not feasible for the customers to accept it. Of course, there are some who use it but it is not at their full capacity. At TECE, we developed our own technology and applied for our patent for the functional layer.

We are working on a strategy to lower the costing of edgebanding to the minimum level to see if we can see a positive reaction from the market. You can get in touch with us to see what we can do together.

Below, you can see our articles and products on this range.