NEWS

TECE vs Other Cheap Edgebanding Comparison Tests

As TECE, we have been producing high-quality edge bands for the furniture industry for many years. In the edge banding sector, quality does not only mean appearance, but also durability, strength, and workmanship.

In the market, we know that especially cheap products of Chinese origin are often preferred. However, the matter does not end with price alone. What about quality? Today, we will answer this question with technical tests.

In this video, we will compare cheap edge bands with our own manufactured products. Our goal is to clearly demonstrate the difference in quality through both visual and technical tests.

This situation seriously reduces adhesion strength and causes the band to peel off easily during use.

The difference is very clear—almost twice as much. Quality primer means longer life. Against stresses caused by heat, humidity, and time, this difference becomes even more apparent.

In TECE edge bands, however, high-density polymer is used, which results in a significantly higher strength value.

This reduces the flexibility of the product and makes it brittle. In addition, the excess inorganic material causes cutting blades in machines to dull much faster than normal.

In this test, we cooled both cheap products and TECE products and tried to bend them. The cheap edge band cracked quickly. The TECE edge band, however, maintained its flexibility under the same conditions. It bent but did not break.

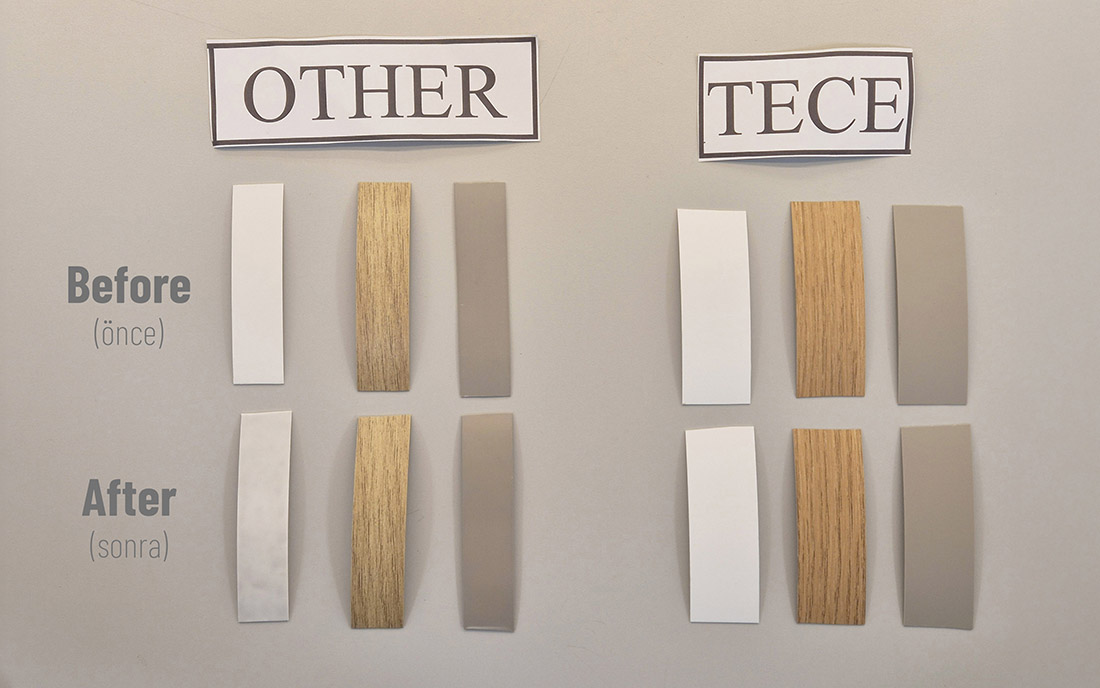

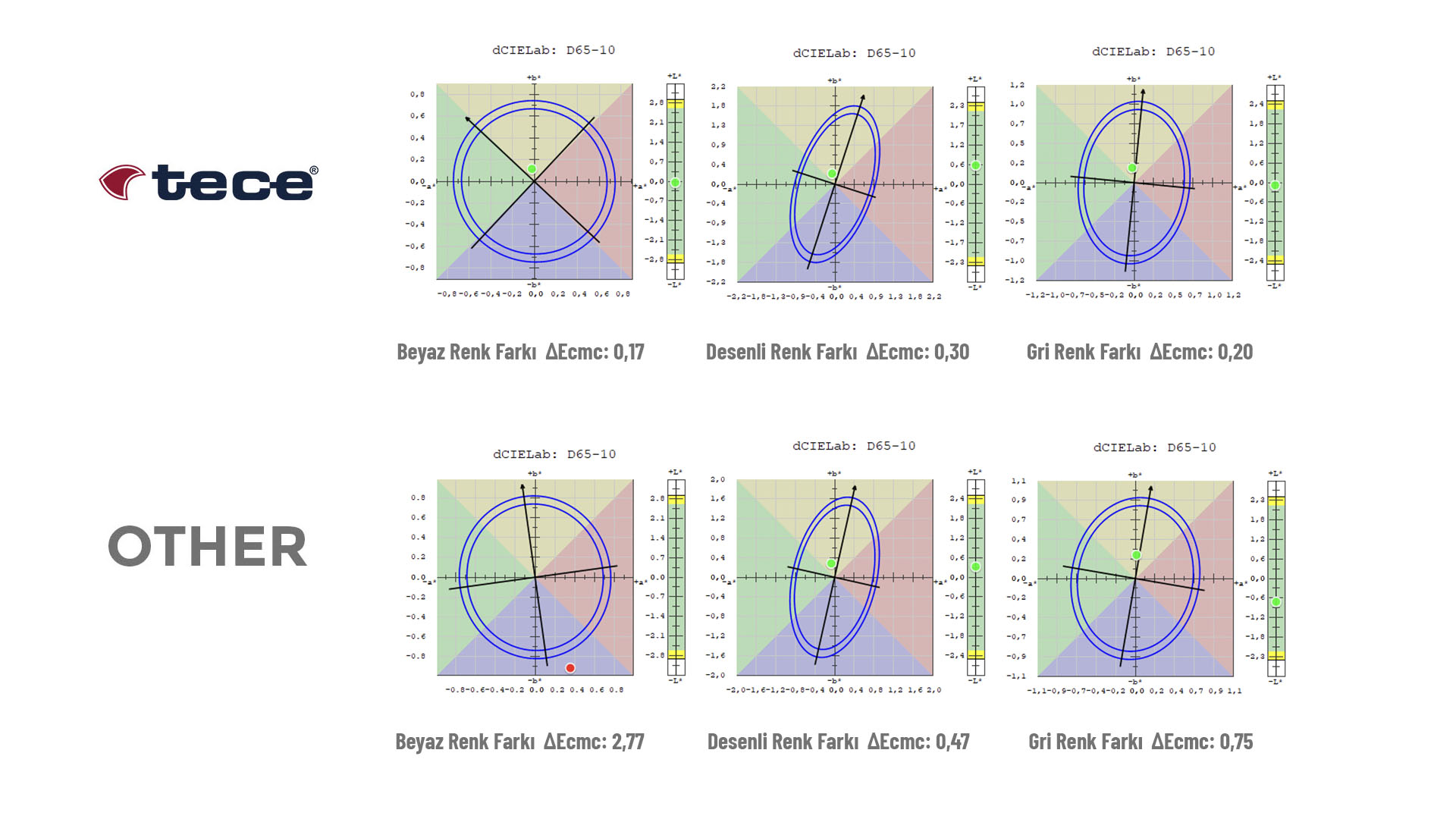

In this test, an outdoor simulation was performed using a xenon arc lamp, with temperature and humidity kept constant. We placed both products in a UV test device for 72 hours and evaluated the results. The printed cheap edge band turned yellow, and in the unprinted white edge band, the color change became visibly noticeable.

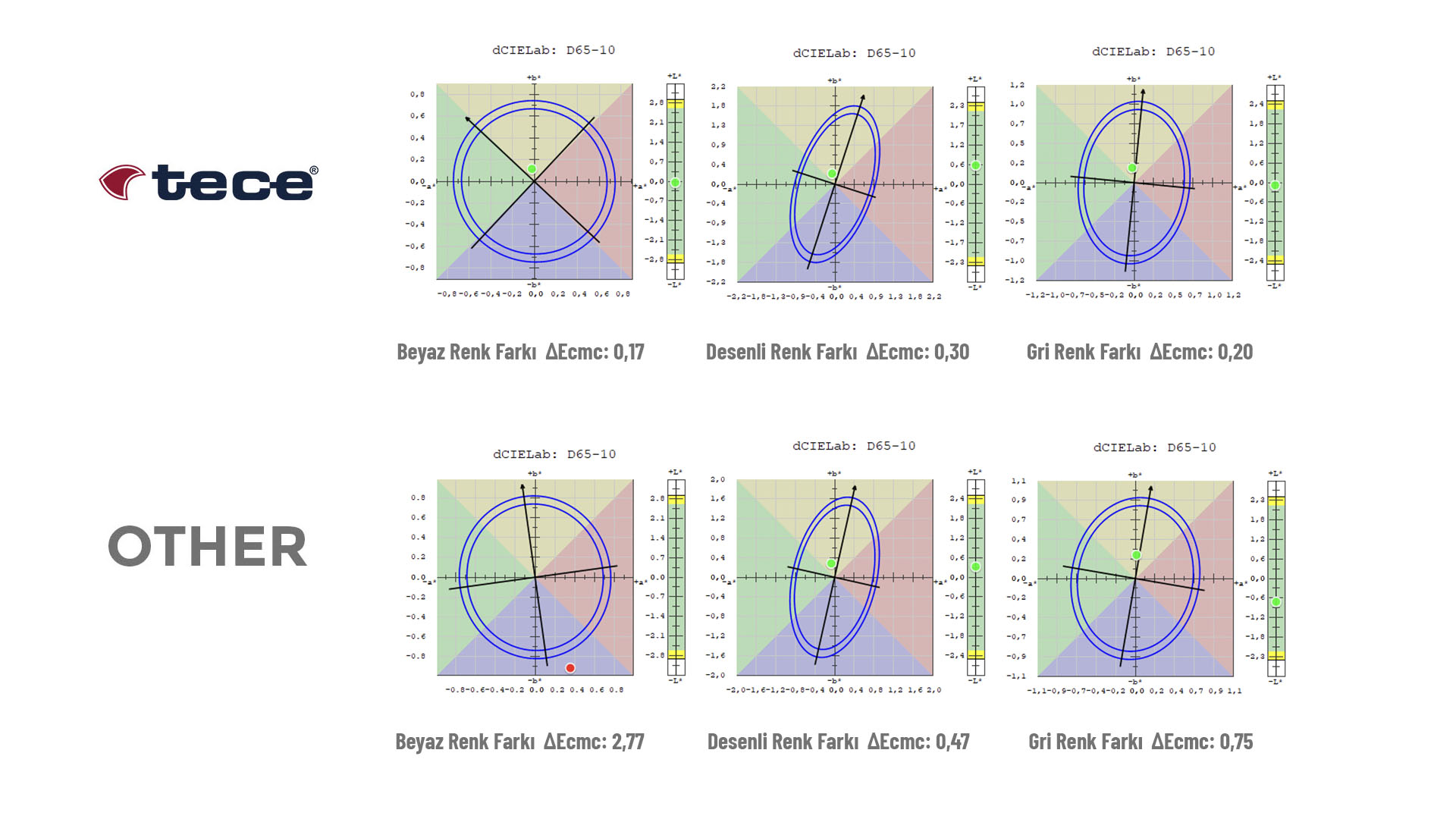

Spectrophotometer measurements showed that in cheap products, especially the white sample, the color difference ΔE value was found to be 2.7.

TECE products, however, showed high lightfastness and retained their color. The measured color difference ΔE value was only 0.3.

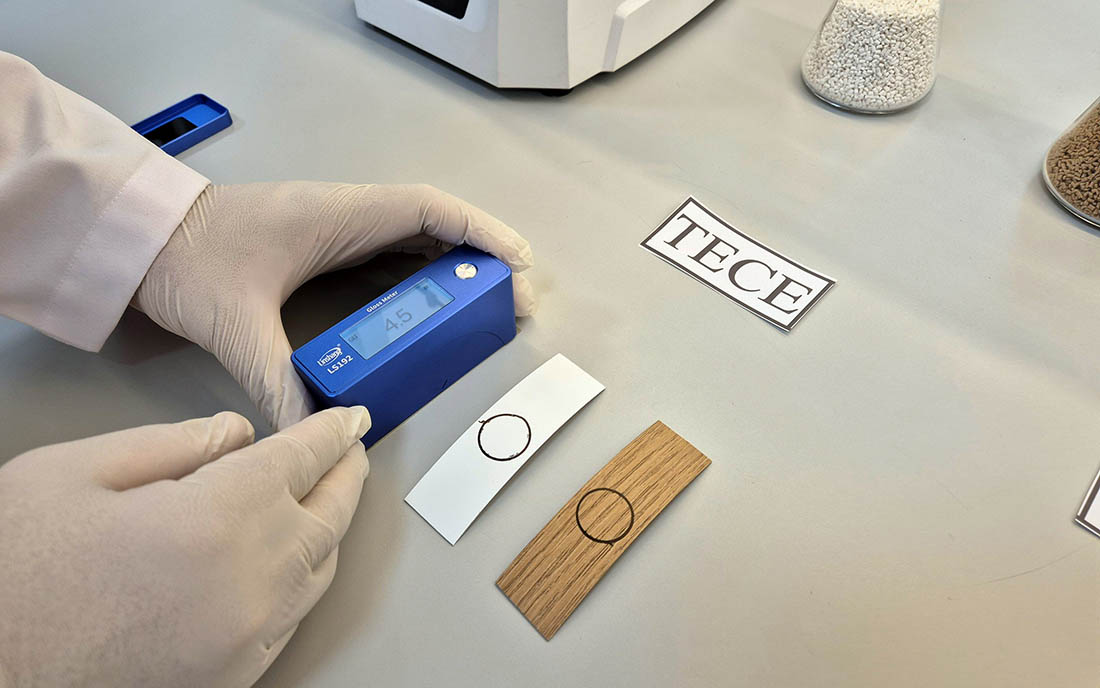

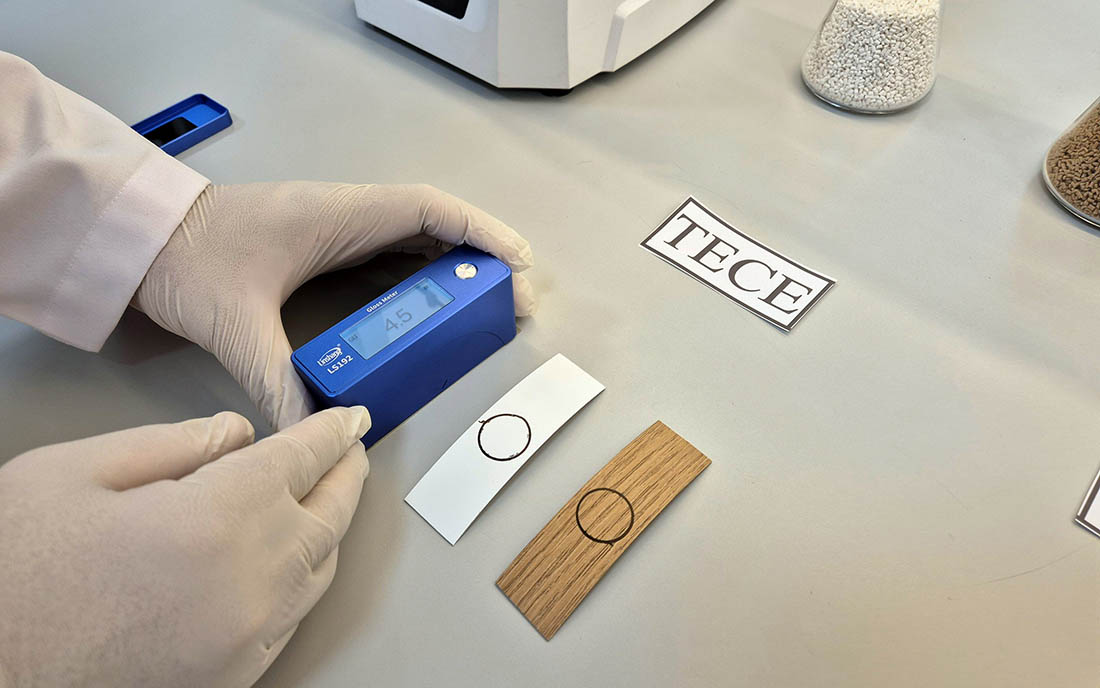

Glossmeter measurements taken before and after the test showed dullness on the surface after applying chemicals.

As part of this test, we applied bleach to the surfaces and examined its effects. In the cheap product, significant dullness and paint fading occurred after bleach application. In the TECE product, however, no change was observed on the surface.

Edge banding is not just a plastic strip; it means quality, continuity, and production safety. Quality production is sustainable success.

Products that look similar on the surface may have completely different internal structures. What matters is not what is bought cheaply, but what lasts long and is of high quality.

As a result, one must consider not only the price but also the quality.

SPANISH:

In the market, we know that especially cheap products of Chinese origin are often preferred. However, the matter does not end with price alone. What about quality? Today, we will answer this question with technical tests.

In this video, we will compare cheap edge bands with our own manufactured products. Our goal is to clearly demonstrate the difference in quality through both visual and technical tests.

1. Primer Application

The adhesion of the edge band to the surface directly affects the lifespan of the product. This adhesion strength is directly related to the quality and amount of primer applied to the surface. When examined under UV light, the amount of primer applied can be seen more clearly thanks to its fluorescent effect. It is clearly observed that in cheap products, the primer application is extremely insufficient, the primer layer is very thin, and in some areas almost no primer has been applied.This situation seriously reduces adhesion strength and causes the band to peel off easily during use.

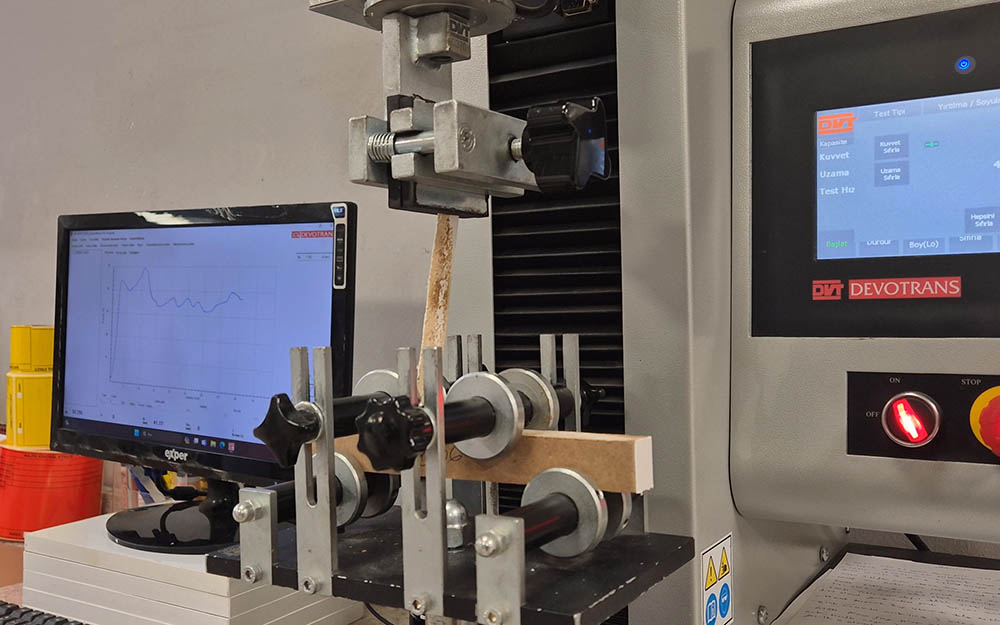

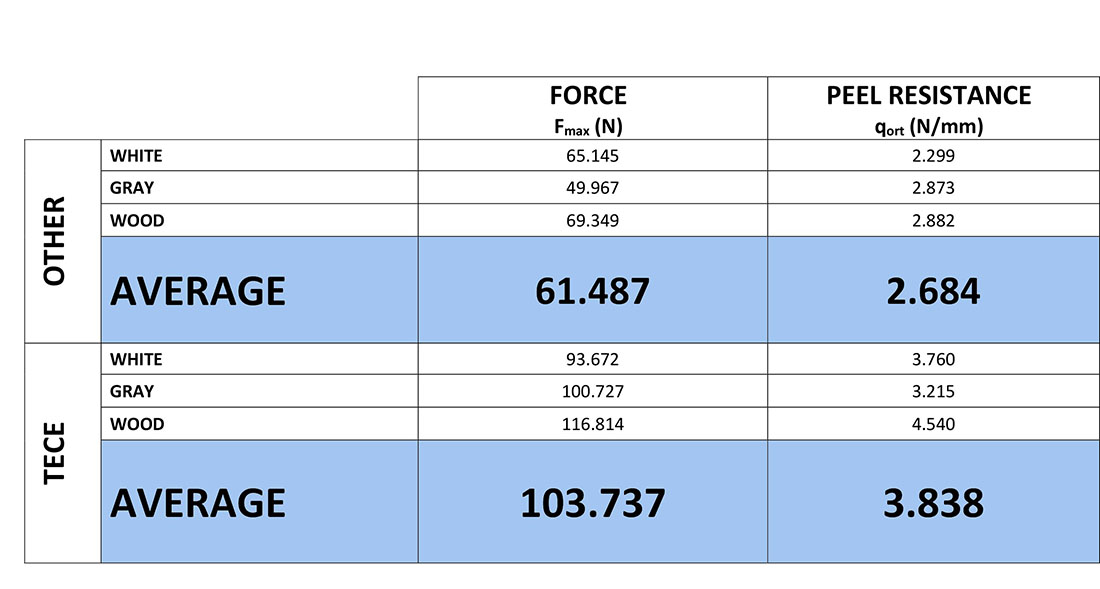

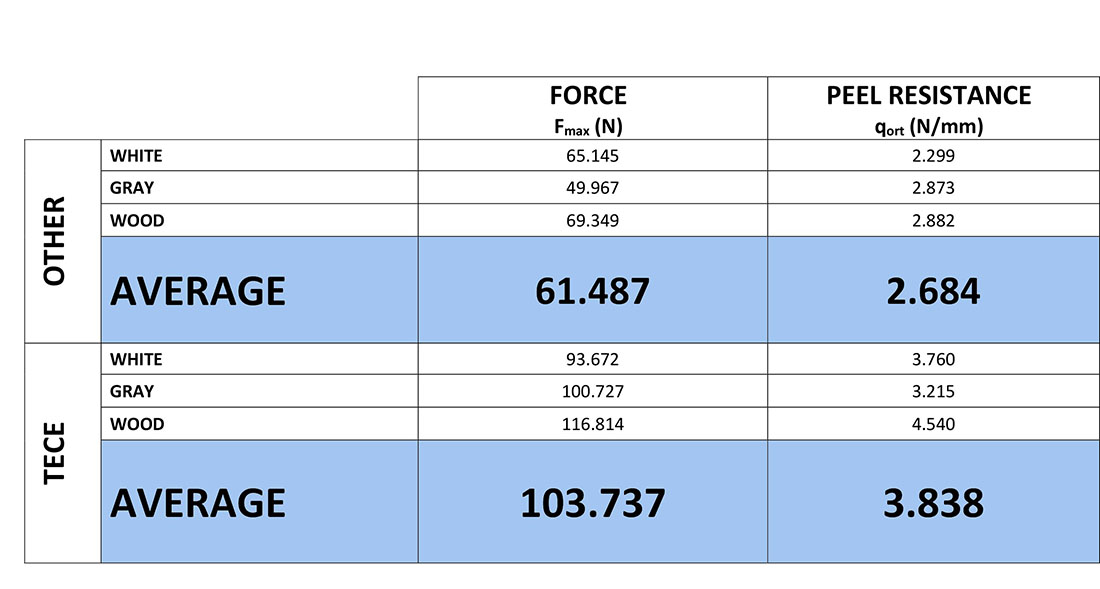

2. Adhesion Strength

We applied both products to MDF surfaces using the same machine and the same adhesive. After resting for 24 hours, we tested the resistance of the bands against peeling with a device. Cheap products, due to insufficient primer application, showed very low resistance against peeling and almost detached from the surface by themselves. Our TECE product, however, remained integrated with the surface.

The difference is very clear—almost twice as much. Quality primer means longer life. Against stresses caused by heat, humidity, and time, this difference becomes even more apparent.

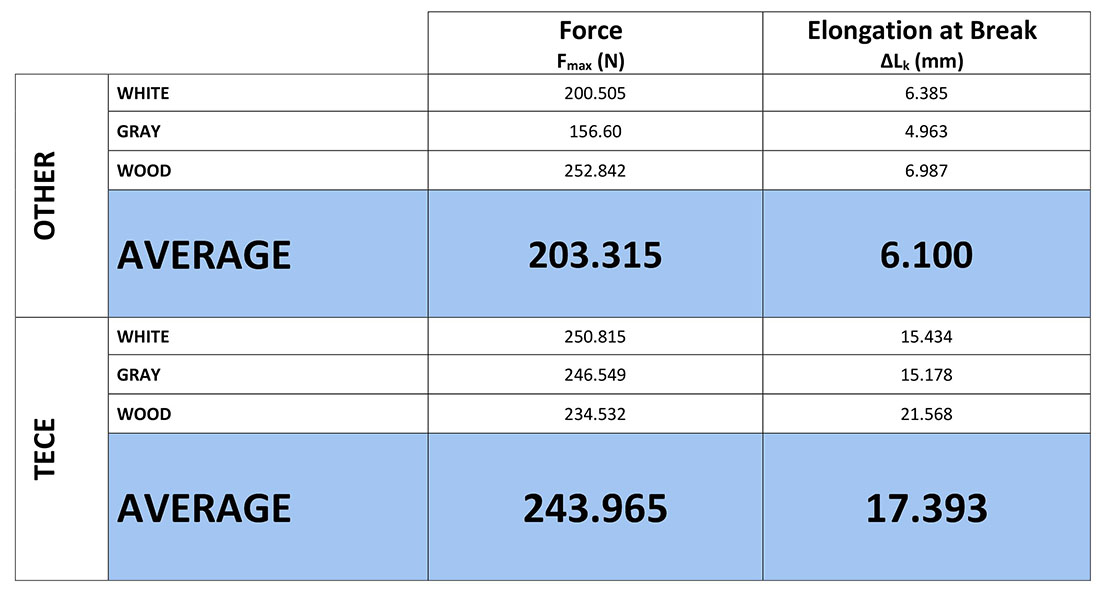

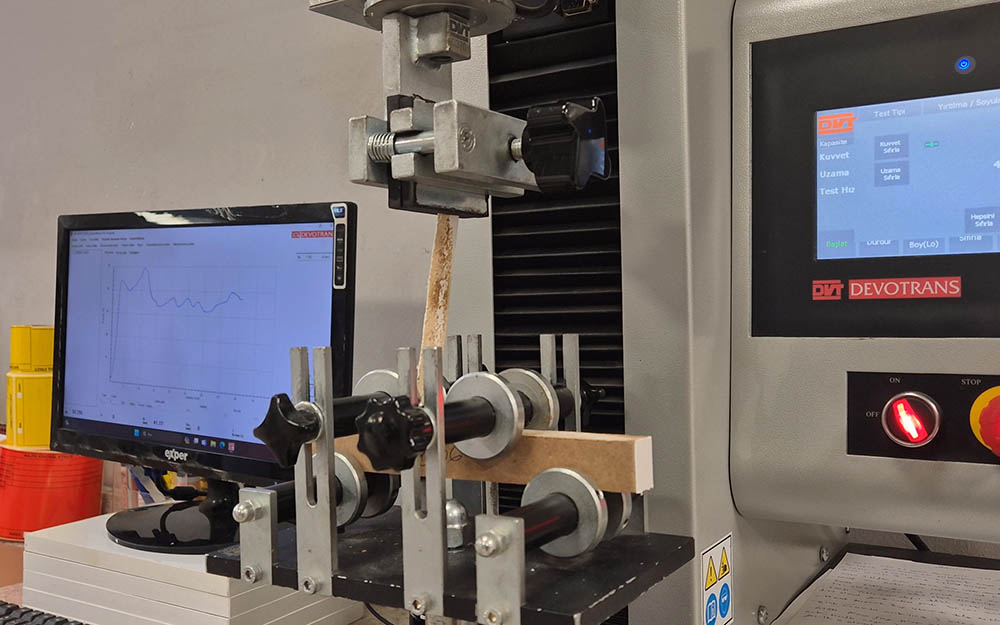

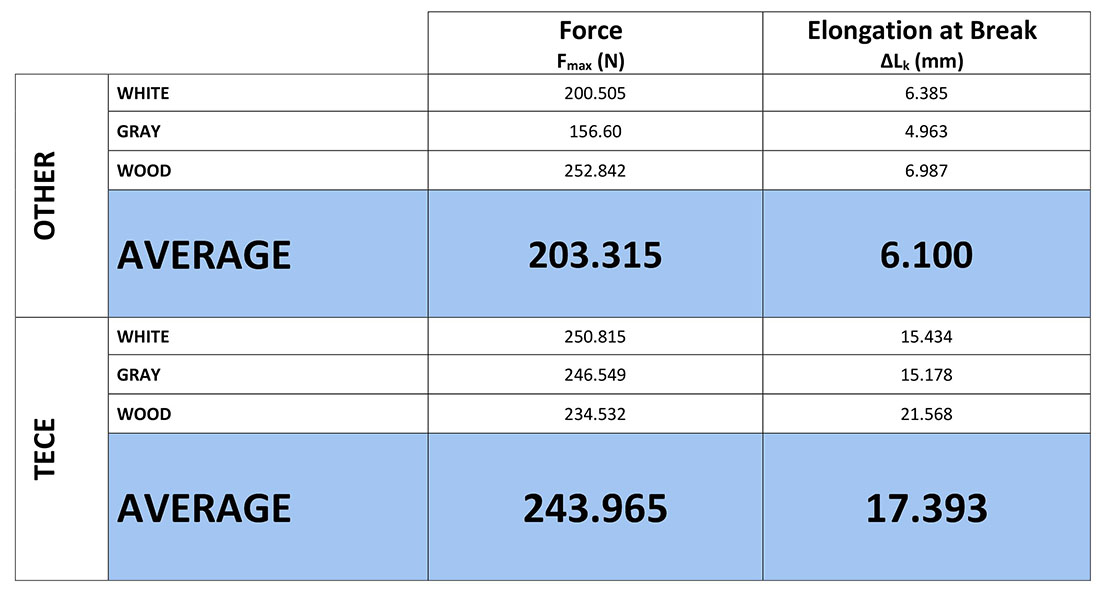

3. Tensile Test

Now we move on to the tensile test. We carry out this test in accordance with ISO 527 standard on samples cut into dog-bone shapes. The results are quite clear: cheap edge bands break under very low force. The reason for this is the excessive use of filler material and the incomplete plasticization process.

In TECE edge bands, however, high-density polymer is used, which results in a significantly higher strength value.

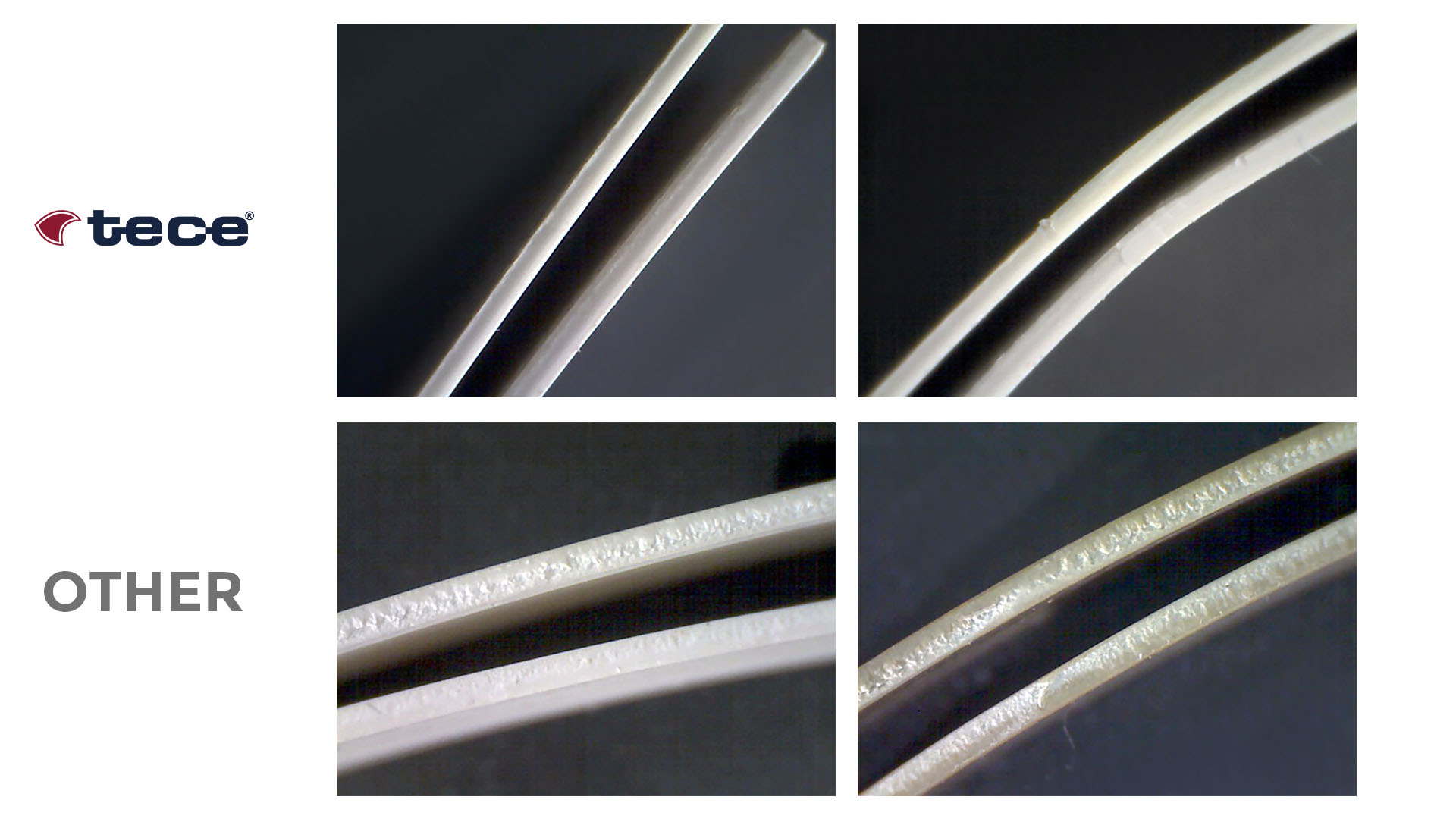

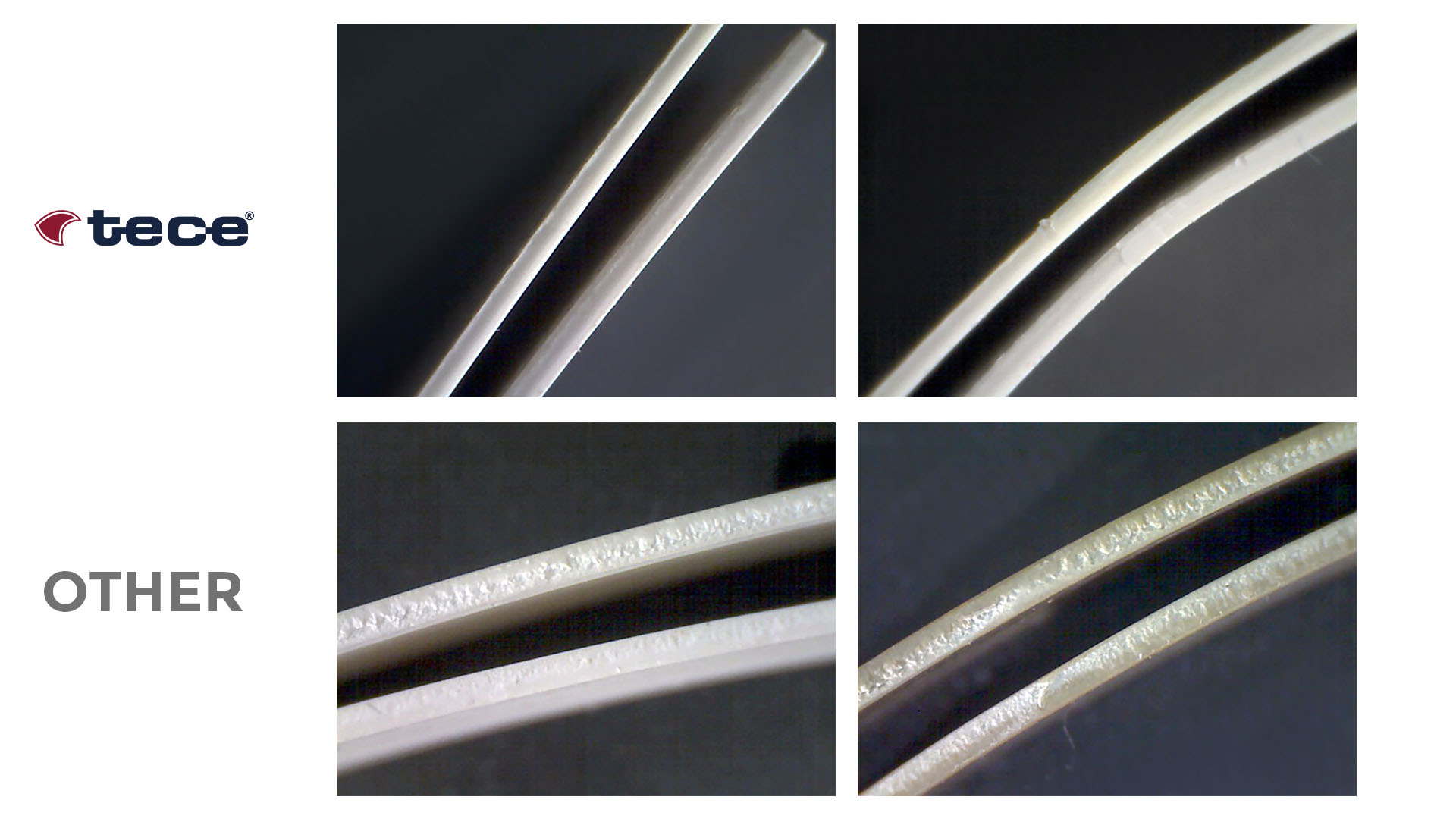

4. Polymerization

When we cut the edge bands in half and film them with a close-up camera, we can clearly see the inner structure. In the vertical cross-section examination, it is obvious that the cheap product has a non-homogeneous structure with a high concentration of fillers.

5. Inorganic Material Analysis

In the inorganic material analysis carried out in an ash furnace at 960 °C, it was determined that cheap products contain approximately 4 times more inorganic material than the amount of filler used in TECE products.

This reduces the flexibility of the product and makes it brittle. In addition, the excess inorganic material causes cutting blades in machines to dull much faster than normal.

6. Brittleness Test

Performance in cold climates is of great importance. Resistance to stretching, impacts, and hot-cold differences during use is required. Bands that crack or do not flex in cold environments cause major problems during assembly.In this test, we cooled both cheap products and TECE products and tried to bend them. The cheap edge band cracked quickly. The TECE edge band, however, maintained its flexibility under the same conditions. It bent but did not break.

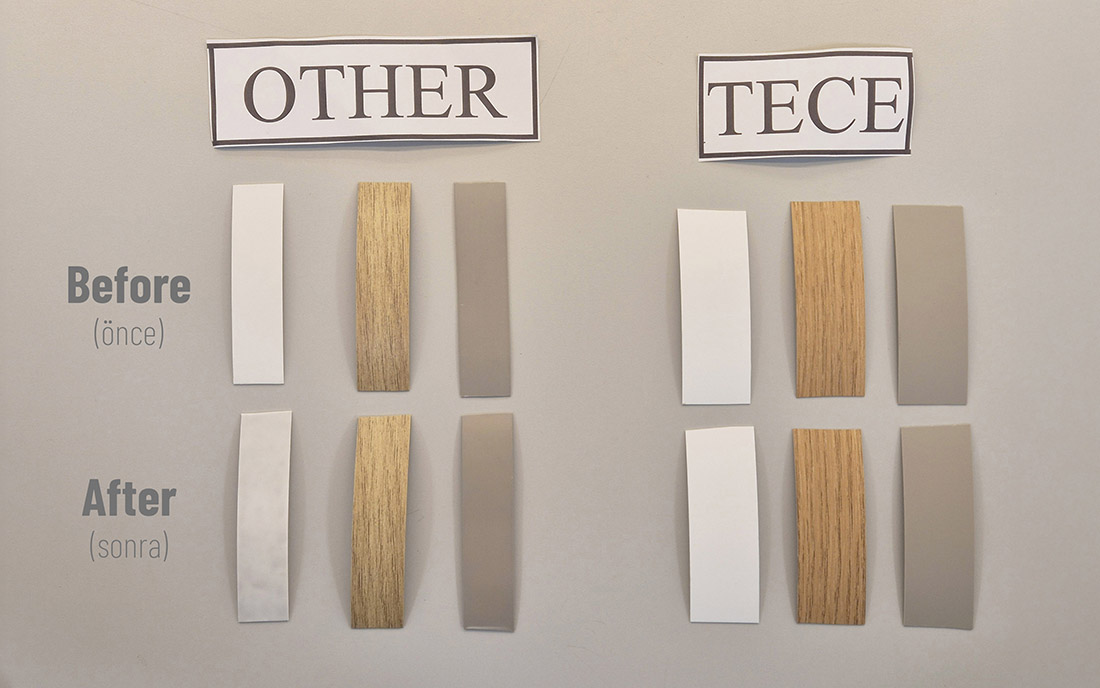

7. Light fastness

In long-term use of furniture, color durability is a critical factor. Fading of colors on surfaces exposed to sunlight or fluorescent lighting is a serious issue.In this test, an outdoor simulation was performed using a xenon arc lamp, with temperature and humidity kept constant. We placed both products in a UV test device for 72 hours and evaluated the results. The printed cheap edge band turned yellow, and in the unprinted white edge band, the color change became visibly noticeable.

Spectrophotometer measurements showed that in cheap products, especially the white sample, the color difference ΔE value was found to be 2.7.

TECE products, however, showed high lightfastness and retained their color. The measured color difference ΔE value was only 0.3.

8. Resistance to Cleaning Chemicals

Chemicals used during cleaning can cause color bleeding and dullness on weak surfaces.Glossmeter measurements taken before and after the test showed dullness on the surface after applying chemicals.

As part of this test, we applied bleach to the surfaces and examined its effects. In the cheap product, significant dullness and paint fading occurred after bleach application. In the TECE product, however, no change was observed on the surface.

Conclusion:

As you can see, the tests clearly demonstrate quality. Cheap products may seem attractive at first glance; however, although they may appear as savings in the short term, in the long run, they cost more due to labor loss, risk of malfunction, aesthetic problems, and customer dissatisfaction.Edge banding is not just a plastic strip; it means quality, continuity, and production safety. Quality production is sustainable success.

Products that look similar on the surface may have completely different internal structures. What matters is not what is bought cheaply, but what lasts long and is of high quality.

As a result, one must consider not only the price but also the quality.

TEST VIDEO ARE BELOW:

ENGLISH:SPANISH: