BLOG

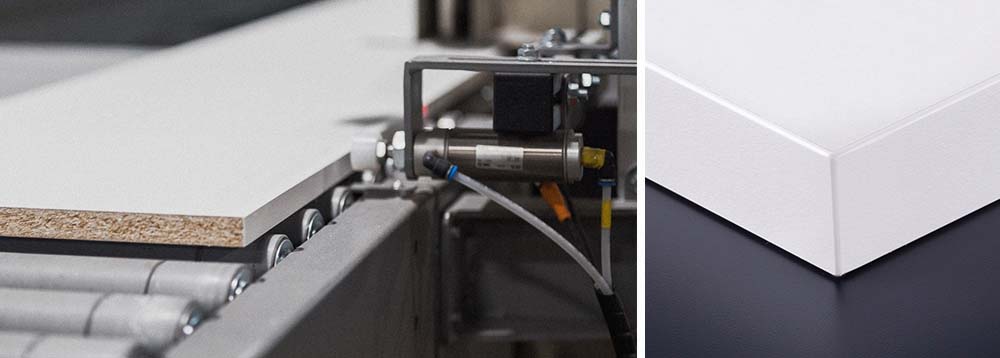

Why Low-Quality Edgebanding Costs You More Than You Think ?

…and How to Stop Losing Money Without Realizing It

In B2B manufacturing, every millimeter matters. And when it comes to edgebanding, many buyers are still falling into the trap of choosing based on price — not performance.But here’s the truth:

🛠 Poor-quality edgebanding isn’t cheaper. It’s just quietly expensive.

Let’s look at the hidden costs no one talks about — and why choosing high-quality edgebanding upfront pays for itself long before the end of the year.

1. Machine Wear: A Silent Profit Killer

Low-quality edgebanding = high blade wear.One major panel processor in Eastern Europe shared that, before switching to Tece, they had to change their edgebander blades every 100 km of poor-quality material.

That meant frequent downtime, constant maintenance, and high replacement costs.

After transitioning to Tece edgebanding, their blade lifespan increased to over 350 km — a 3.5x improvement, directly cutting tooling costs and boosting production efficiency.

2. Storage Chaos = Space & Capital Drain

Low-quality edgebanding often means poor consistency in color, tension, and thickness.So what happens? You overstock, hoping to "adjust manually later."

That excess? It eats valuable warehouse space and ties up your working capital in unsellable meters.

Tece clients report up to 27% reduction in safety stock after switching to consistent, color-stable rolls.

3. Defect Rates: The Hidden Margin Leak

Every glue failure, curl, or misaligned color is a hidden refund, remake, or reputation hit.And each of those is a cost you didn’t plan for.

The worst part? These defects usually show up after production — when it’s too late to react without losing money.

Tece’s zero-defect rate commitment and advanced surface bonding reduce return rates to less than 0.5% per project batch.

4. What You’re Really Paying Over a Year

If you compare the yearly hidden cost of bad-quality edgebanding (machine maintenance + stock loss + defects), it often exceeds the price difference between:

• A low-cost, unstable brand, and

• Tece’s high-quality edgebanding

Across hundreds of customers, we’ve seen the same equation:

👉 The total real cost of poor quality = 2 to 3x the price gap you tried to save.

Conclusion: Choosing Tece Isn’t a Luxury — It’s a Long-Term Gain

In the world of panel processing and furniture manufacturing, quality isn’t a bonus — it’s a profit-preserving decision.

o More efficient machines

o Fewer stock risks

o Less waste

o Better customer satisfaction

o Stronger brand positioning