For professionals in furniture manufacturing, flawless edgebanding is key to maintaining quality and client satisfaction.

Even small mistakes can lead to costly defects, wasted materials, and unhappy customers.

Here’s how to avoid the top three application mistakes.

1. Surface Preparation

Dust, grease, or rough edges can stop adhesives from sticking properly, leading to peeling or gaps. Always clean and smooth the surfaces before applying edgebanding.

Additionally, make sure edgebands are at room temperature before use to avoid cracking or adhesion issues during the manufacturing process.

Why It Matters:

- Poor application can lead to early failures, affecting durability and client satisfaction.

- Adhesive performance suffers when applied to dirty or rough edges.

2. Using Incorrect Temperature Settings

Adhesives need precise temperatures to bond effectively. Incorrect settings can cause weak adhesion or no-adhesion at all to the boards.

Why It Matters:

- Low temperatures can lead to incomplete bonding, causing premature peeling.

- Excessive heat may misshape materials like PVC or ABS.

Pro Advice:

- Follow manufacturer guidelines

- Calibrate equipment regularly to maintain accurate temperatures.

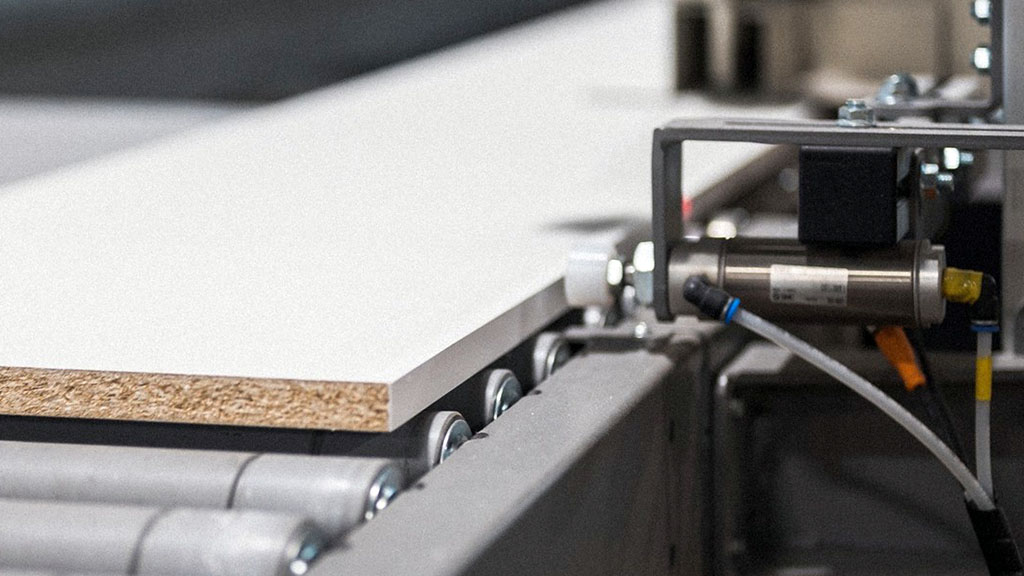

3. Proper Pressure Application

Insufficient or inconsistent pressure can cause air bubbles, weak bonds, or misaligned edges.

Why It Matters:

- Irregular pressure can lead to weak spots where peeling starts.

- Misaligned edges affect the product’s appearance and perceived quality.

Pro Advice:

- Maintain pressure rollers for smooth application.

- Use a roller tool for consistent pressure along the edge.

- Check alignment before applying pressure for a clean finish.

Bonus Hack: Maintain Your Equipment

Even the best techniques fail without well-maintained machinery. Dull cutters or misaligned rollers can effect results.

Pro Advice:

- Schedule regular equipment checks and replace worn parts rapidly.

- Train staff to identify early signs of equipment wear to prevent bigger problems.

Key Takeaways for Application

- Prepare surfaces: Clean, sand, and ensure edgebands are at room temperature.

- Get temperature right: Calibrate tools and follow guidelines.

- Apply pressure evenly: Use rollers and ensure proper alignment.

- Maintain equipment: Replace worn parts and train staff on upkeep.

Contact Tece Dekor today to explore ranges designed specifically for professionals like you!